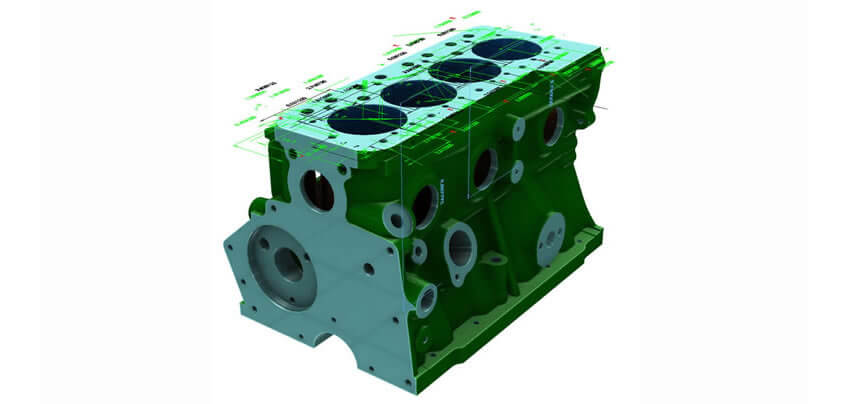

Case Study : A-Series engine block

The “A Series” engine was used from the 1950’s by the British motor industry in a wide range of small cars, including the original Mini. It doesn’t seem very long ago when you could readily find an old donor engine, even a high specification Cooper S engine, inexpensively. Those days are now gone, with the supply of original parts almost dry. Engine builders face not only higher cost but also the logistical issue of locating blocks on demand.

Performance Projects was approached to reverse engineer a specific variant of “A Series” engine block, and provide all the necessary CAD models and detail drawings to enable remanufacture. Three old blocks were used, not one, to derive the CAD model, so as to ensure any anomalies of one block were not carried over to the CAD model. Research was undertaken to fully understand the original design; for example, which features were used as datums on the original production line, and which features were machined for each variant. Modifications that would have been made by engine tuners in the 1960’s were incorporated, with slight adjustments to the casting made to allow those modifications to be made reliably. Close liaison with foundries and machine shops ensures that the features desired for cost effective modern manufacturing methods were included.