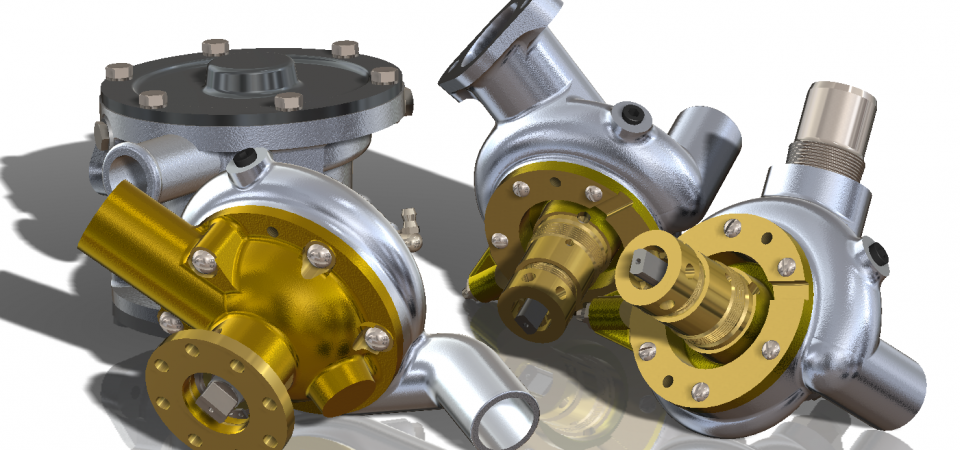

Case study : Lagonda Water Pumps

Enabling resupply of durable water pumps for pre-war Lagondas

David Ayre Cars Ltd are specialists in Bentley, Invicta & Lagonda car preparation and component supply. Their customers have cars that often need new water pumps, but original spare parts are long gone, and pattern parts feature the same shortcomings as the originals. The brief for Performance Projects was clear: to design replacement Lagonda water pumps that look and perform exactly like the originals, but without their durability & maintenance issues.

The solution was to design pumps with redesigned internals to reduce leakage and improve durability. To keep the look and performance of the originals, the same the original body and impeller castings were retained.

The original water seals, in common with many cars of this era, feature a gland type seal. A grease or tallow impregnated cord is wound around the pump shaft, inside a cavity in the pump housing. A “gland nut” is then tightened down onto cord, enough to stop it leaking. The design is prone to leakage, which at best creates staining on both the car and the garage floor. If not regularly attended to, leaks can be more serious, or ultimately cause the pump to seize.

The new replacement David Ayre Cars Ltd pumps all use a modern, mechanical seal, as typically used on modern cars. They require no maintenance, and are effectively leak free.

The shafts in the original pumps spin in a greased plain bearings, located on the “wet” side of the seal. Because they run in the engine coolant, they are prone to problems with corrosion, grease degradation, and dirt within the coolant damaging the bearing surfaces. The revised pumps rolling element bearings are individually sealed, and are positioned on the dry side of the main seal. To avoid corrosion further, the impeller shafts are made of stainless steel, rather than the original non-stainless items.

Performance Projects Ltd supplied a comprehensive set of computer models and drawings in electronic format (CAD data). In contrast to the old manual drawings, the CAD data allows David Ayre Cars Ltd to manufacture the pumps with the latest machinery: the cost savings offset the cost of design work, and give more precisely made components.

Through using Performance Projects’ trusted and proven design services, marque specialist David Ayre Cars Ltd are able to fulfil customer demand for high quality Lagonda water pumps.

******

Performance Projects undertakes design and engineering programmes for the motorsport, niche vehicle and historic markets. Contact us here to see how we can help.