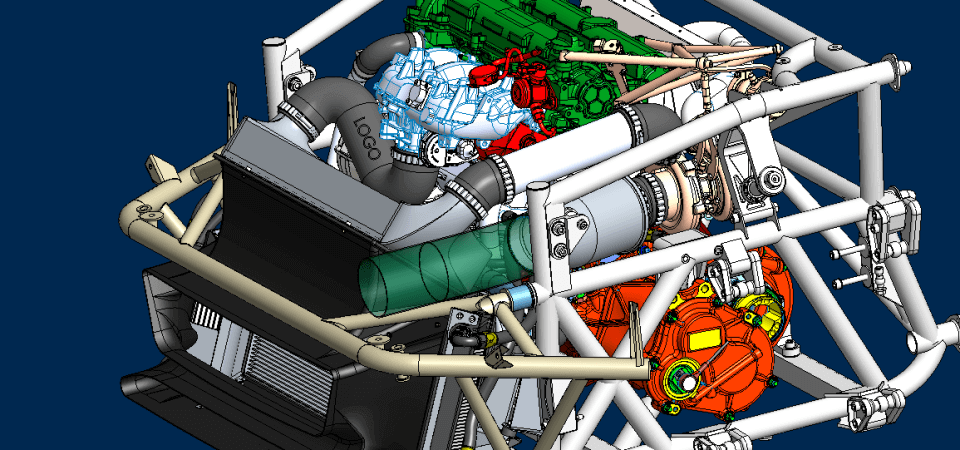

Case study : BTCC Cooling Package

BTCC team ‘Rotek Racing’ approached Performance Projects after repeatedly experiencing severe engine overheating which had resulted in a number of very expensive engine failures and highly public failures to finish.

Performance Projects reviewed the installation and undertook some preliminary analysis before recommending a new cooling system installation with a revised layout, new duct with greatly improved aerodynamic efficiency, and more effective sealing design. The main cooler cores were retained, allowing existing stock to be used and so keeping costs down. The design used a CNC machined mould tool for speed of turnaround and tolerance control, with traditional GRP wet layup component manufacture to minimise ongoing component cost.

Rotek Race Engineer Ryan Imperial comments “We unveiled the new cooling package at Oulton Park and noticed a “substantial difference”, immediately fielding enquiries from other teams about who had undertaken the redesign. The introduction of the package marked a threshold in the team’s season, with no further failures to finish or unexpected expense through engine overheating failure. No longer having to worry about cooling issues, the team able to concentrate on lap time improvement and make a substantial improvement on race results.