Unique, High Profile, Demonstration Vehicles

At Performance Projects we undertake complete niche vehicle design and builds. The headline features of such a vehicle may include the powertrain, radical styling, and unique features. But beyond those headlines is a wide range of more mundane but essential systems that require close attention to detail.

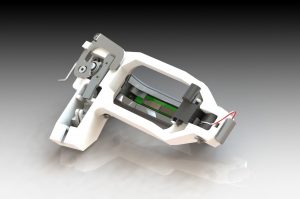

Performance Projects undertook the engineering and project management of a complete vehicle build, using a new donor vehicle and repackaging the powertrain, electrical systems and driver interface to look like an entirely different vehicle. As one part of this project, the styling and packaging called for a completely new bespoke door handle assembly. The handle interfaced with a stock door latch mechanism with central locking, and featured illumination, keyless entry and a conventional keylock. The handle was counterbalanced so that, in the event of a crash, the handle cannot fly open due to its inertia.

The chassis was made of SLS (“3D printed”) glass reinforced polymer, the external components and latch components machined from solid, with the electronics for the keyless entry “potted” into the handle.

The finished door assembly worked beautifully, one of many elements contributing the quality feel that the customer would want and expect from such an expensive one-off vehicle.