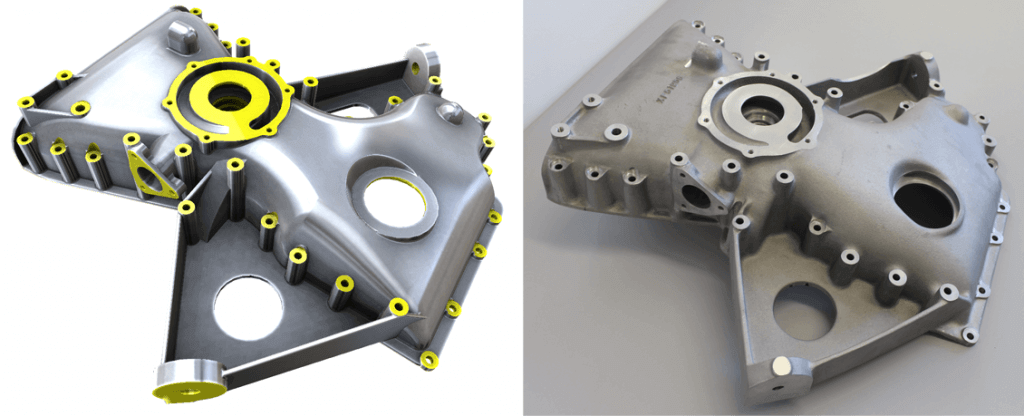

Aston Martin front covers

Imagine you are a marque specialist who has both the tooling and the original drawings for a key component. You’ve even remanufactured the parts before. Surely it is easy to undertake another production run? Unfortunately the transfer of manufacturing suppliers from manual process to computer numerically controlled (CNC) means that the supplier base machining purely to drawings is becoming increasingly small, variable in quality and requiring longer leadtime.

Performance Projects was approached by a leading Aston Martin specialist with exactly this problem on engine front covers for ‘DB’-variants. Performance Projects used copies of the original drawings and an example of a raw casting to create a computer aided design (CAD) model of both the casting and the machining detail. New drawings were then created in CAD to confirm the model accuracy and allow rapid distribution of the components electronically to a much wider supplier network.

The upfront cost of undertaking the computer design was recovered by the competition of a larger supplier network and the efficiency of machining from CAD compared to manual machining, even for a production run in single figures. Furthermore, the use of modern machinery has ensured higher quality, repeatable products.